Macgregor Historic Games/Rose & Pentagram Design

| Ancient lathes | Continual rotation lathes | Spring-pole lathes |

| Bow lathes | Tools | Related Machines |

| Specialty Lathes | Quotes about turning | Notes on a 17th Cent. turner |

| My bow lathe | Bibliography | Links |

| Ancient lathes | Continual rotation lathes | Spring-pole lathes |

| Bow lathes | Tools | Related Machines |

| Specialty Lathes | Quotes about turning | Notes on a 17th Cent. turner |

| My bow lathe | Bibliography | Links |

Specialty Lathes and Related Attachments

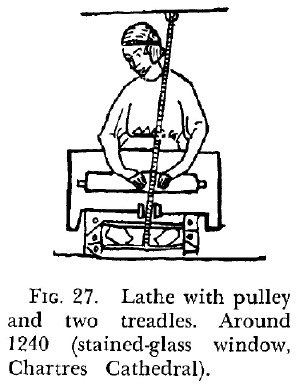

An interesting treadle lathe operated while seated and with two foot treadles. The opposite ends of the strap are tied to the two treadles providing a back-and-forth motion to the work like a spring-pole lathe. In this example the strap appears to go up through a pulley in the ceiling? I have seen a better illustration of a Chinese version of this type set-up that I am trying to track down where I saw the illustration so I can add it as well.

Scanned from Daumas' A History of Technology & Invention Vol. I.

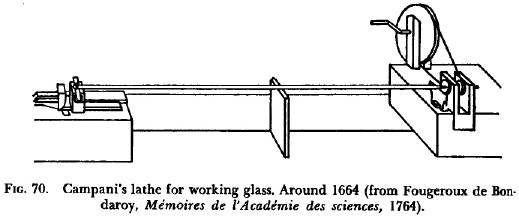

A lathe for cutting threads from Theatre des Instruments Mathematiques, by Jacques Besson. The lead screw is placed in the center of the lathe and pulls a vertical tool that cuts the piece to the right of the worker. Suspended weights help to provide pressure on the tool and regulate the movements.

Scanned from Daumas' A History of Technology & Invention Vol. II.

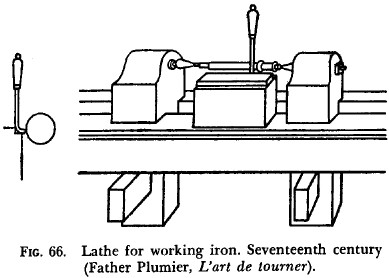

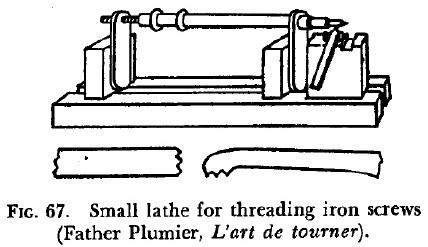

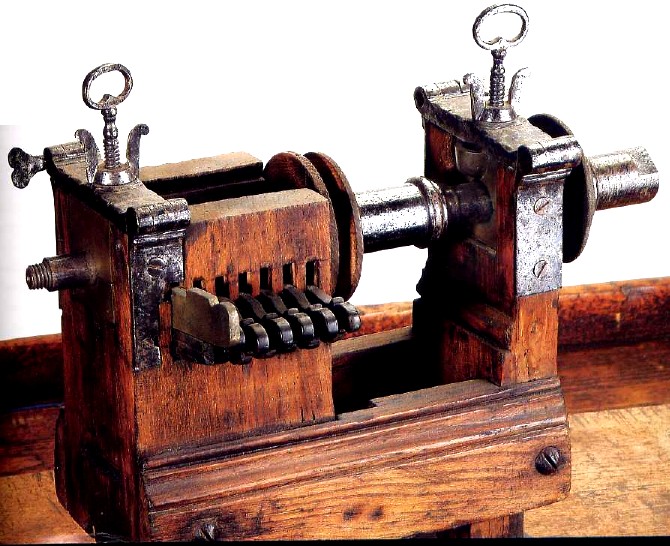

Plumier's screw-cutting lathe consists of shaft with a threaded screw attached to it's left end and acted as a lead screw to move the entire shaft back and forth. The piece to be threaded was mounted in the chuck at right, and the threads where roughed out with a graver, or sharp chisel and then finished with a "comb" which was filed to the proper profile for the finished threads.

Plumier's screw-cutting lathe consists of shaft with a threaded screw attached to it's left end and acted as a lead screw to move the entire shaft back and forth. The piece to be threaded was mounted in the chuck at right, and the threads where roughed out with a graver, or sharp chisel and then finished with a "comb" which was filed to the proper profile for the finished threads.

Scanned from Daumas' A History of Technology & Invention Vol. II.

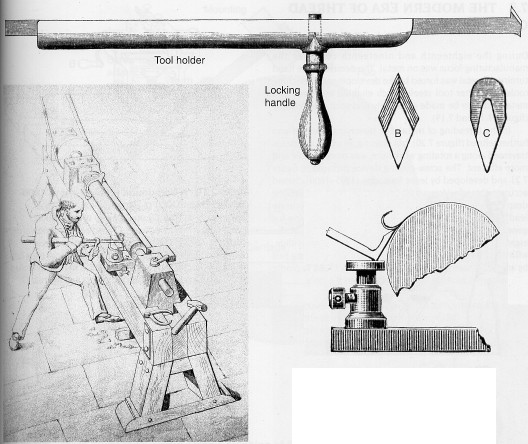

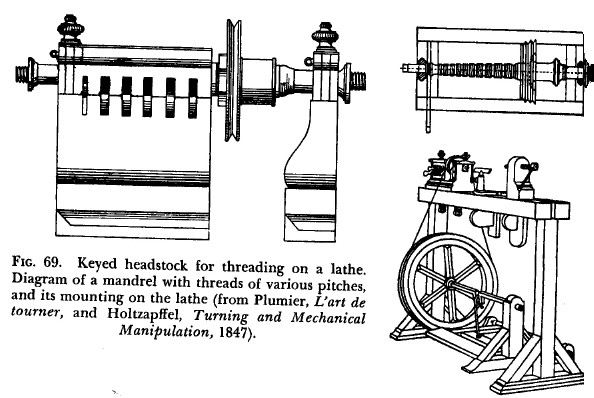

Daumas says that this type of keyed headstock making possible to turn threads of varying pitches was used only by amatuers and was not used by professional until the middle of the 18th century. The keyed headstock was placed on the lathe, enclosing a portion of the mandrel, on which the series of threads of various pitches were already cut. Several "keys" or levers corresponded to each set of threads, and one would be raised to select the pitch of thread needed.

Scanned from Daumas' A History of Technology & Invention Vol. II.

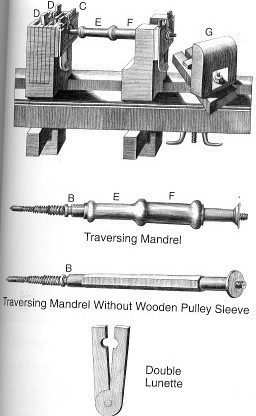

Traversing-Mandrel Headstock 1701.

Traversing-Mandrel Headstock 1701.

From Plumier. The mandrel has three varying lead screw threads in the left-hand end, allowing for three different pitched screw-threads. The double lunette is wedged in place around the selected lead screw. An unthreaded lunette can be used in the mandrel's grove "B" if the turner did not want the mandrel mocing back and forth. Scanned from M. Darlow's Woodturning Techniques.

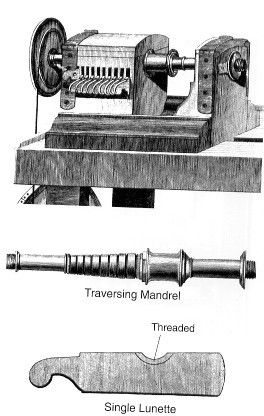

Traversing-Mandrel Headstock, circa 1800.

Traversing-Mandrel Headstock, circa 1800.

From Bergeron's Le Manuel du Tourneur. An advanced version of the previous headstock with a choice of eight different thread patterns to chose from. The lunettes being used again held in place by wedges. A few decades later the selection of multi-threaded mandrel was replaced by a shorter mandrel using interchangeable threaded collars Scanned from M. Darlow's Woodturning Techniques.

Traversing-Mandrel Headstock.

Traversing-Mandrel Headstock.

A photograph of a headstock some to the those illustrated above. Scanned from

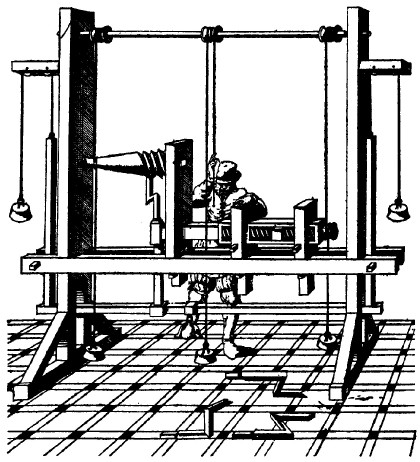

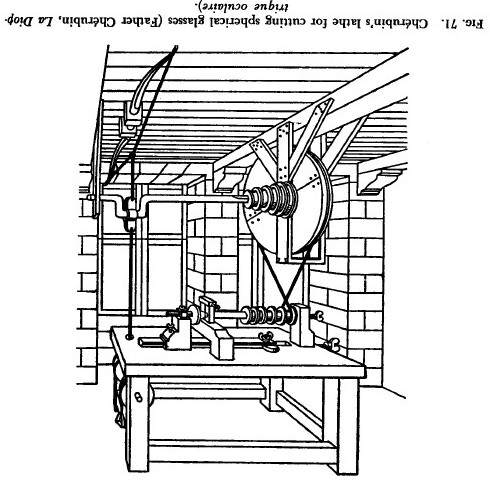

In his La Dioptrique Oculaire (1671) Father Cherubin described various lathes he had adapted for glassworking. The operator stood at the left and pumped a stirrup hanging below the table which is attached to the overhead crank. An overhead bow works as a spring to assist the rotation of the crank on the up-swing. A series of pulleys on the shaft of the crank provided varying speeds.

Scanned from Daumas' A History of Technology & Invention Vol. II. The image was accidentally inverted in the book, so I flipped it after scanning it.

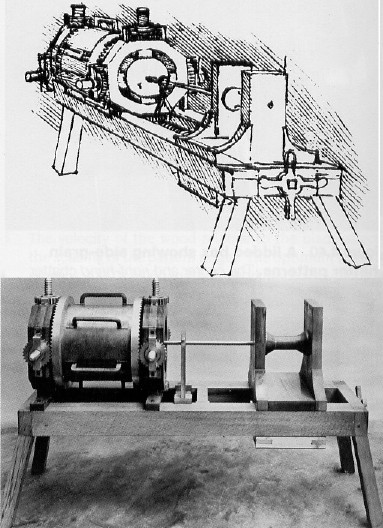

Leonardo Da Vinci's boring machine

Leonardo Da Vinci's boring machine

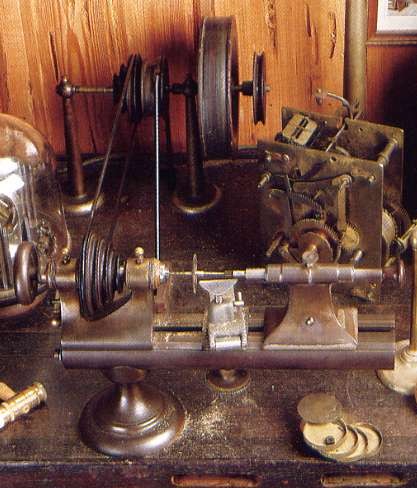

Watch-maker's Lathe

Watch-maker's Lathe